1. High Accuracy : Rigorous quality and precision controls are carried out during the manufacturing process of High Precision NIBL Korta Ball Screws using sophisticated measuring systems ( Laser Pitch Measuring, Profile Projectors, Continuous Torque Meters, etc ). Measurements are carried out in controlled atmosphere room eliminating distortion due to ambient conditions.

2. Smooth Operation and High Efficiency : The extremely low rolling friction coefficient of ball screws in comparison with sliding friction of conventional screws increase the efficiency of NIBL Korta Ball Screws.

3. High Rigidity and Minimal Axial Play : NIBL Korta Ball Screws are preloaded in order to eliminate backlash, increase the overall rigidity of the Ball and Nut system, and to improve the positioning accuracy and repeat-ability.

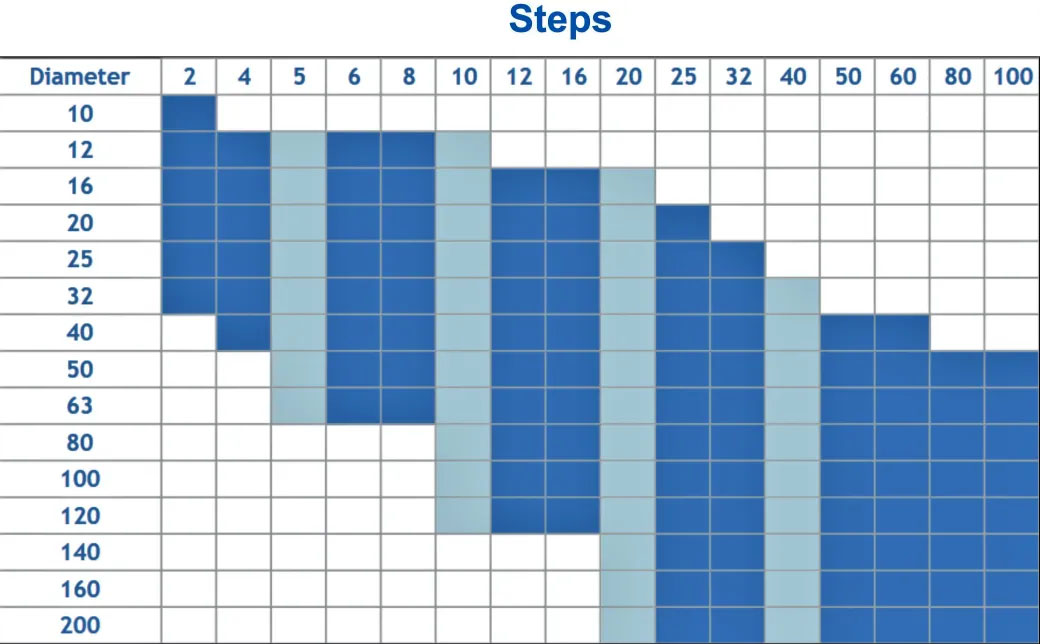

The Ball Screw production sizes are shown below. Check characteristics by clicking on each nut type.

1. Single Nut

| BS (DIAM. 50-100): WITH DIN 69051 FLANGE |

| BS (DIAM. 120-200): WITH DIN 69051 FLANGE |

| BS (EXTRA LONG LEAD): WITH DIN 69051 FLANGE |

| BS (TWO STARTS): WITH DIN 69051 FLANGE |

| BSL: CENTRAL FLANGE |

| BSR: ROTATING NUT |

| KBS: WITH DIN 69051 FLANGE (Stock) * |

| RBS: WITH FLANGE (Stock) * |

| RS: WITHOUT FLANGE (Stock) |

2. Double Nut

| DBS (DIAM. 12-40): WITH DIN 69051 FLANGE |

| DBS (DIAM. 50-100): WITH DIN 69051 FLANGE |

| DBS (DIAM. 120-200): WITH DIN 69051 FLANGE |

| EDBS: WITH DIN 69051 FLANGE (Stock) * |

| UDBS: WITH FLANGE (Stock) * |

* Includes STP file downloading.

* For any other design consult the Technical Department.